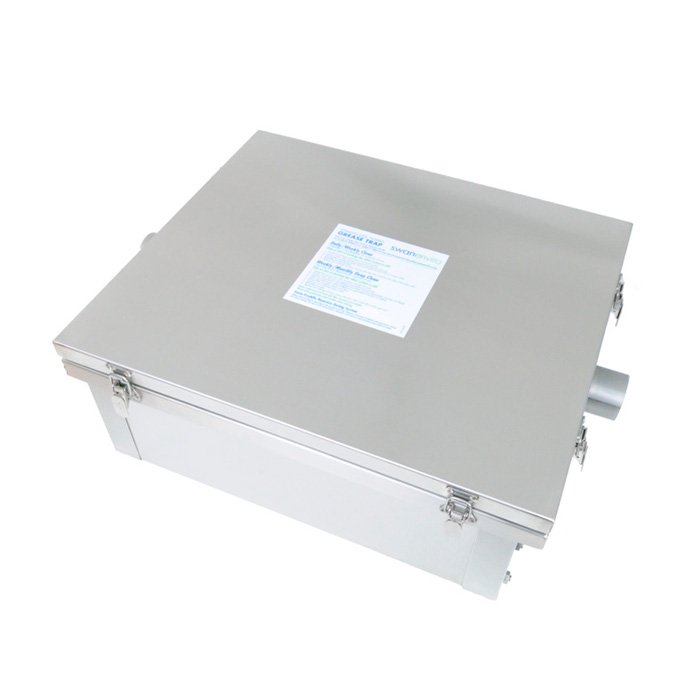

Grease traps

Better designed. better built.

Overview

- Patented design helps maintain water quality to the highest standards.

- Single sink or multi-sink.

- Capable of handling dishwasher outflow.

- Requires a minimum of space to install and operate.

- Easy to retro-fit.

- Built to deliver years of service.

- Integrated access for grease reliquifier (if specified)

- Internal or external use (above ground)

- Through flow unit, serves any sink/dishwasher volume where recommended installation and cleaning procedures are followed

- High quality type 304 stainless steel Construction

- All seams fully welded

- Connection using standard Multi-fit connectors

- Quick release watertight lid for simple inspection and cleaning

- Full maintenance instructions supplied

- 2-year return to base warranty.

Available in a range of sizes our Grease Traps can be either free standing or wall mounted to suit both new designs and existing establishments and once installed are low maintenance giving years of reliable performance with minimum attention.

Features

- Traps grease and kitchen debris

- Minimal maintenance

- New installations or retro fit

The patented stainless steel Grease Traps range is designed for efficient operation and extra long life. From small domestic to large volume food processing applications, they are better built and better value.

Sizes of Grease Traps

- Traps grease and kitchen debris

- Minimal maintenance

- New installations or retro fit

The patented stainless steel Grease Traps range is designed for efficient operation and extra long life. From small domestic to large volume food processing applications, they are better built and better value.

Applications

Useful anywhere water quality counts

Swan Freshflo® Dosing Units are in use throughout the UK, helping businesses of all types and sizes to work more efficiently and comply with local regulations.

Swan Freshflo® Dosing Agent colonises your waste pipe system, providing continuous action.

Commercial

Bistro, Bakery, Cafe, Hotel, Nursing Home, Restaurant, Social Club, Takeaway, Works Canteen

Industrial

Factories, Food Packing, Food Processing, Industrial Units, Workshops

Domestic

B & B, Guest House

Not sure what you need? We have probably done an installation just like yours and can help with useful information. Let us know what you want.

2-Year Return To Base Warranty

If it’s our fault, we’ll fix it.

For a period of two years from date of purchase, we will replace a faulty unit by return on receipt of the Dosing Unit and proof of purchase, subject to appropriate application, correct installation and use according to instructions.

How it works

The Swan Grease Trap is a patented design developed over years of serving the demands of the UK catering industry.

The filtration system removes fats, oils, grease and solid matter from waste water before it enters the drain. It is a passive system, so there is no need for a circulation pump or other apparatus.

- Waste water runs into the Grease Trap from the sink/dishwasher.

- As waste water enters the trap, lighter fat, oil and grease separates and floats to the top whilst solid particles settle down to the bottom of the stainless steel filter cassette.

- As the trap drains, waste water is drawn down through the filter cassette, reducing turbulence and filtering out more solid matter.

- The filtered water runs up through the integrated air trap to the main drain.

- The addition of the Swan Enviro Dosing Unit adds a measure of bio active fluid that helps break down solid grease, allowing it to flow out with the waste water. This is added at the end of the working day, allowing the dosing agent to work overnight.